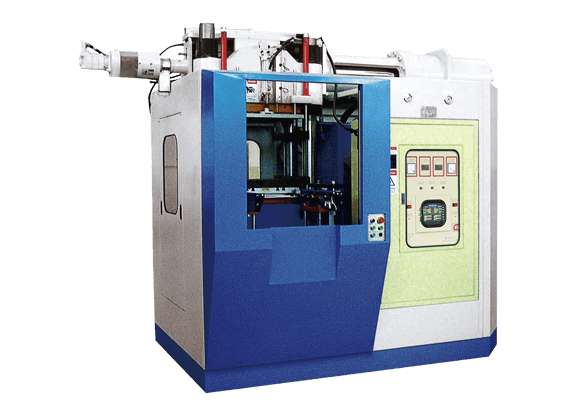

Applications

Polygon, polyhedron, and other complicated products. Especially in sports, medical, automobile, and electrical applications.

Process

The rubber molding process is to heat rubber material at 120–180°C to vulcanization, then injection into the mold, and finally get the rubber end product after cold down.

Suitable for

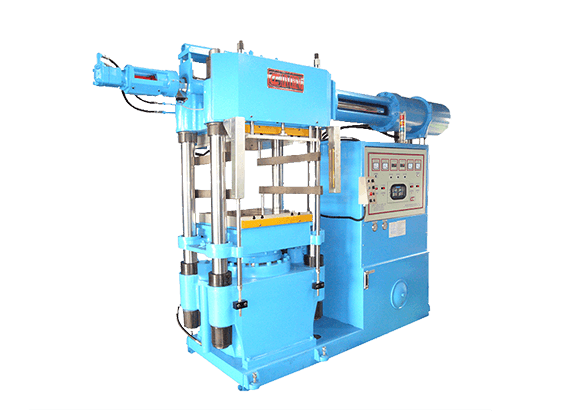

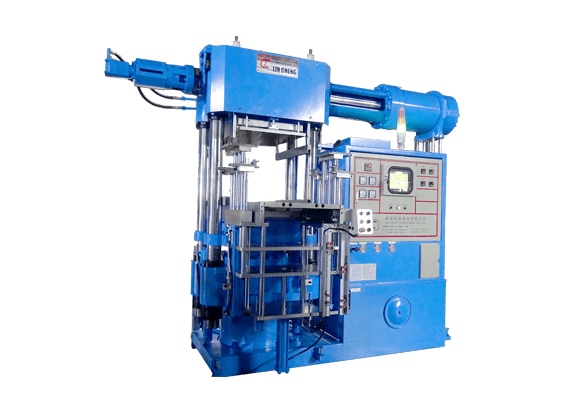

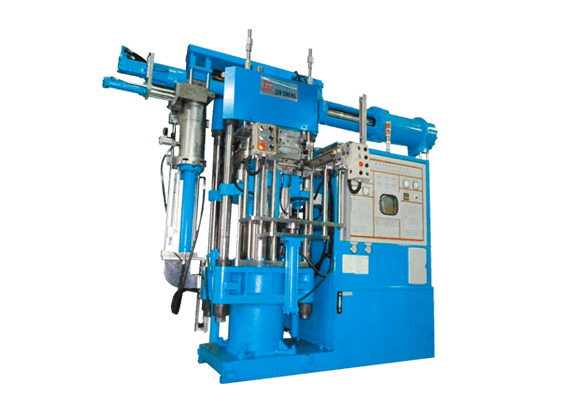

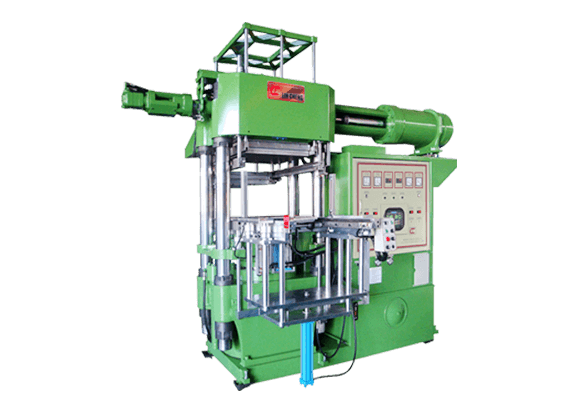

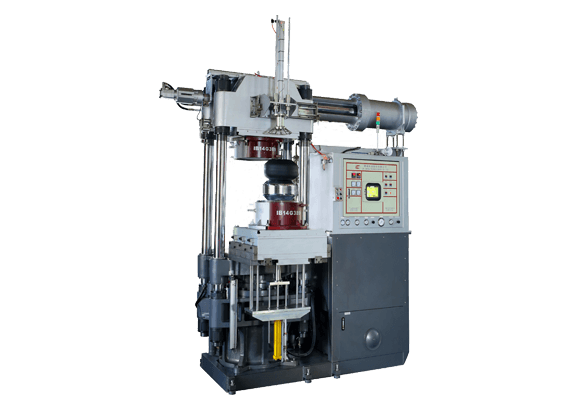

Rubber injection molding machine :-

Nature rubber

Rubber of metal boned parts

Oil resistance rubber

silicone rubber

Synthetic rubber

Medical/Pharmaceutical usage rubber

Heat resistance rubber

-

Solid silicone rubber