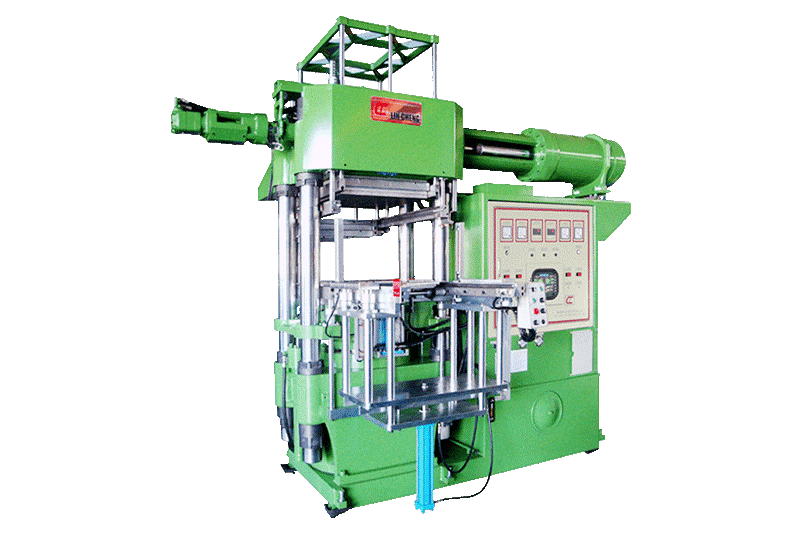

Non-runner-waste Rubber Injection Molding Machine

Home / News & Exhibitions / Non-runner-waste Rubber Injection Molding Machine

For more than four decades Lin-cheng Technologies has shown its great expertise around the world in creating exclusive services for customers. We stand out in the field for manufacturing rubber injection molding machines, silicon rubber injection molding, vacuum compression molding, thermoforming, thermosetting, carbon fiber molding, powder forming, and other types of compression molding machines. The way Lin-cheng pursues its goals is to create automated functions, minimize labor requirements, energy-saving and much better quality to customers.

Combines Green Energy, Energy Saving, and Automation

2RT Mold-open Non-runner-waste Rubber Injection Molding Machine

In 2023, green energy, material energy-saving, and automation have all become indispensable advantages. The biggest advantage of Lin-cheng in 2023 is to improve the efficiency of production by upgrading the functional design of each machine.

Among them, the upgrading of "green energy" and the development of technology can effectively solve the problem of rubber waste in the production process. These upgrades incorporate a Cold-runner injection solution, Auto loading, Auto mold cleaning, Auto material arrangement, Auto de-molding, Auto discharging, Auto fetching, and other features...

The performance of this year (2022) can grow by 15-20% compared with last year, and the production line will remain fully loaded before the second quarter of next year (2023). In the face of doubts about inflation and future prosperity, we will be prepared and cautious.

Lin-cheng continued to pay attention to the changes in industry and consumer needs and decided to boost our professional knowledge and technical fields and development to improve efficiency and machinery. Also emphasize in quality, so that customers have higher performance and high efficiency in production. Nevertheless, since Lin-cheng has mastered every step needed to follow the automation trend, the expectation for the upcoming year 2023 is to keep providing more diversified machinery models to our customers.

We are sure that in 2023, we will provide better technical services and promote our high-quality products all over the world so that domestic and foreign markets have enough confidence in Lin-cheng.

We not only provide high-quality and high-reliability machinery but also provide one-stop service for customers, including specification discussions and design, quality pre-sales and after-sales service guarantees, and an operation guide. If you are interested in getting in touch and knowing more about what Lin-cheng’s has to offer for Automated Rubber Silicone Injection Molding Machinery, do not hesitate to visit their website through the links below.

Source: PRM-Taiwan Blog