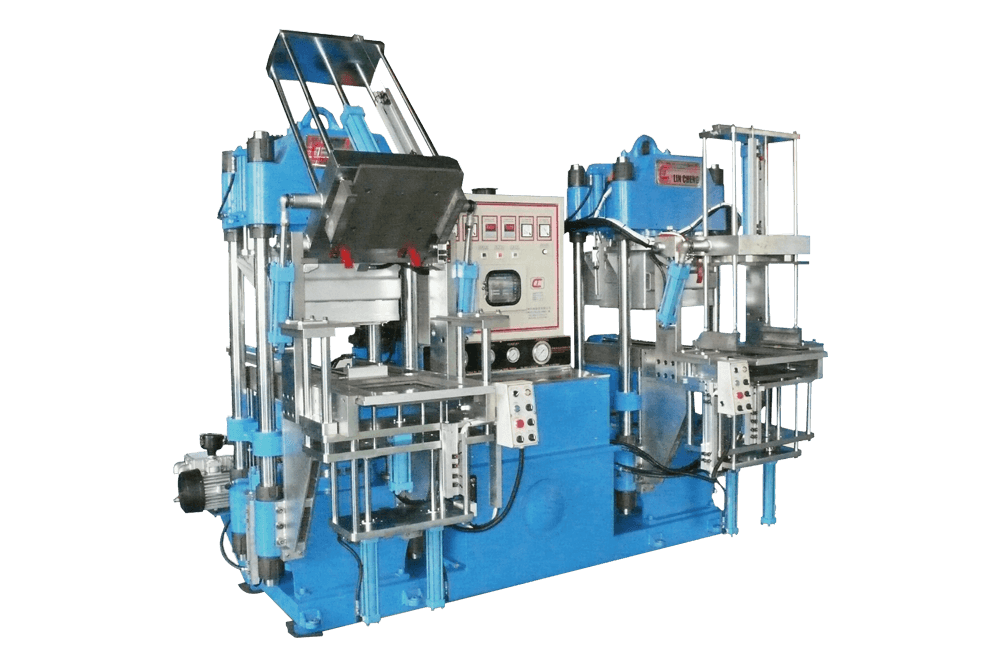

4RT Mold-Open Oil-Seal Vacuum Compression Molding Machine

VOCC-D3W/P1-2-5

Home / Our Products / Vacuum Molding Machine / VOCC-D3W

Features

-

Design for machine frame

The frame of the vacuum compression molding machine is made of steel plates through the assembly. It is suitable for the production of oil seals.

-

Design for loading/unloading molds

Abrasive components are installed on the frame for loading/unloading molds. It can be frequently used and its positioning is very accurate.

-

Design for vacuum compression room

A vacuum compression gate can be opened or closed very quietly and smoothly. The tightness is excellent and it is capable of being a high percentage of vacuum.

-

Design for oil tank

The vacuum compression room and the oil tank are separated to make oil seals more durable.

-

Design for final products

Two openings are designed for the final products, top, and bottom. The operation is easy and the production speed is very fast.

-

Maintenance

All positioning switches are installed outside the vacuum compression room. It becomes more durable and it is easier to perform maintenance work.

-

Hydraulic system Design

The hydraulic system is designed by proportional pressure and flow ratio, which is the steady, quiet, and low frequency of malfunction. Two shafts can be operated simultaneously.

4RT Mold-Open Oil-Seal Vacuum Compression Molding Machine

Specifications

| Diameter of piston (mm) | 225 | 250 | 300 | 400 |

|---|---|---|---|---|

| Clamping force (ton) | 80 | 100 | 150 | 250 |

| Stroke (mm) | 200 | 200 | 200 | 200 |

| Heating platen (mm) | 250*300 | 350*400 | 450*480 | 570*610 |

| Mold board size (mm) | 290*320 | 390*420 | 500*520 | 620*620 |

| Horse (hp) | 5 / 10*1 | 7.5 / 10*1 | 10 / 15*1 | 10 / 15*1 |