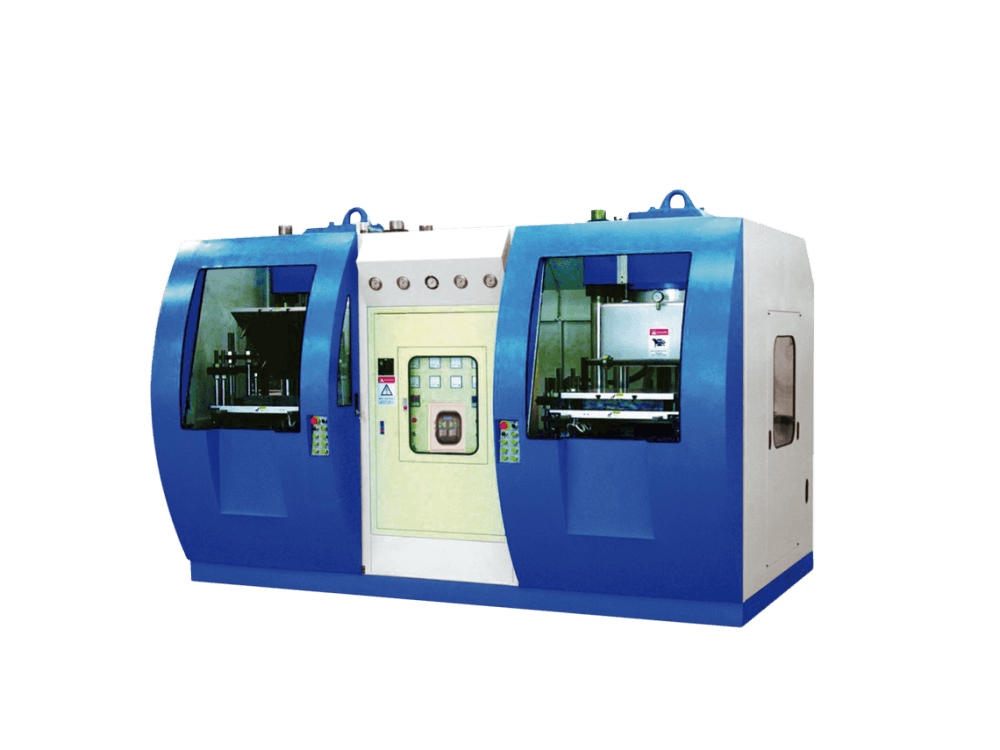

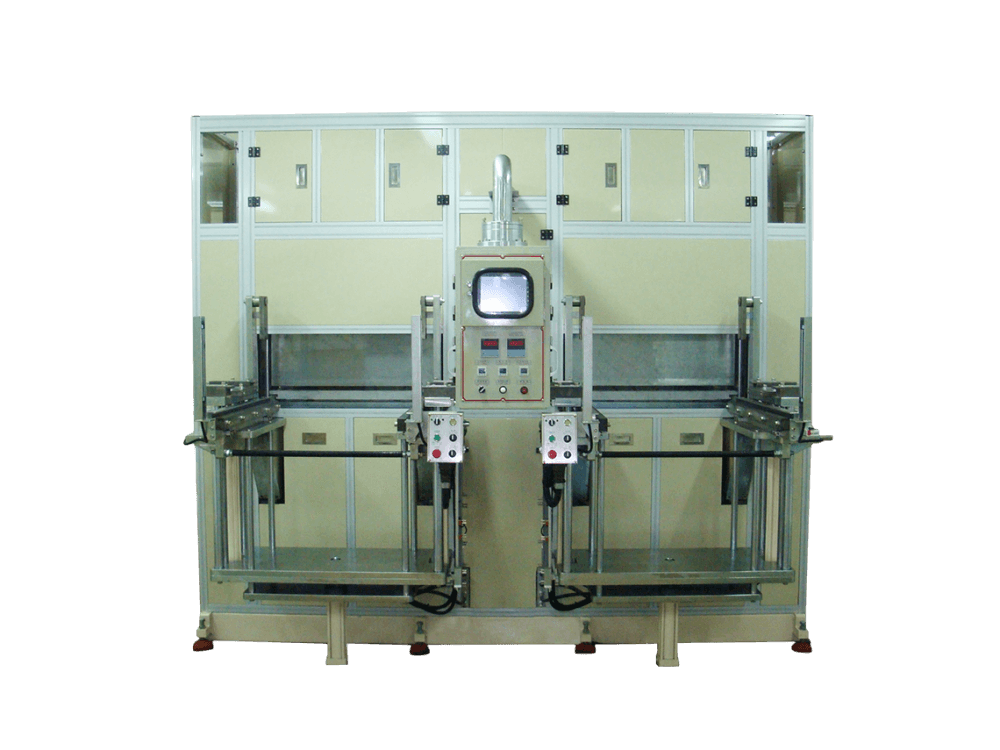

CE Certificate Vacuum Compression Molding Machine

VCC(CE-TYPE)/P1-2-7

Home / Our Products / Vacuum Molding Machine / VCC(CE-TYPE)

Features

-

Safety design

A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators.

-

Vacuum capability

It is capable of being high percentage of vacuum. An Average vacuum method is adopted to make products steady and to promote the quality and throughput.

-

Mold lifting design

Incorporate a special design into the mechanism of mold lifting. It is durable, quiet, speedy and stable.

-

Hydraulic system design

Double motors(large tons) and individual hydraulic system are adopted. It is steady, quiet and low frequency of malfunctions. Two stations can be operated simultaneously.

-

Mold calibration

Two type of mold calibration are provided for users to choose from, fast type and slow type. It makes the calibration safer and more accurate.

-

Mold position

Molds can be precisely positioned. A 100% safety design for positioning is available to prevent molds from damage.

CE Certificate Vacuum Compression Molding Machine

Specifications

| Diameter of piston (mm) | 250 | 300 | 350 | 400 | 450 | 560 | 700 | 800 | 960 |

|---|---|---|---|---|---|---|---|---|---|

| Clamping force (ton) | 100 | 150 | 200 | 250 | 300 | 500 | 800 | 1000 | 1500 |

| Stroke (mm) | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 500 | 900 |

| Heating platen (mm) |

UP400*400 DN420*450 |

UP450*450 DN480*500 |

UP503*508 DN554*640 |

UP600*600 DN650*740 |

UP600*600 DN650*740 |

UP600*600 DN650*740 |

UP850*850 DN910*940 |

UP1000*1000 DN1200*1300 |

UP1500*1500 DN1800*1900 |

|

UP700*700 DN740*800 |

UP700*700 DN740*800 |

||||||||

| Horse (hp) | 7.5/10*1 | 10/15*1 | 10/15*1 | 10/15*1 | 10/10*2 | 15/15*2 | 20/20*2 | 20 | 30 |